Art & Design Case Studies

From 700 BC Until Forever: Preserving an Ancient Assyrian Relief with Artec Eva at the British Museum

Summary: The British Museum has held more than 200 square meters of an ancient Assyrian relief since the 1850s. They decided to scan it in high-detail 3D.

The Goal: To scan the relief panels using handheld, structured-light 3D scanners to capture in precise detail the full 205 square meters of the relief. Then to create 3D models of the reliefs.

Tools Used: Artec Eva, Artec Studio

How often have you had the urge to reach for a vase, necklace or dagger behind the glass when you’re at a museum? Pick it up, roll it about in your hands and just take a closer look at it from all sides?

Touching and feeling an exhibit may still be a pipe dream, but now that the idea of digitizing collections in 3D is catching on at more and more museums and galleries around the world, turning an exhibit and viewing it from different angles is becoming a reality.

You can now do so with the British Museum’s unique collection of Assyrian reliefs, which were 3D scanned by CyArk at the end of 2014 using the Artec Eva. Founded in 2003, CyArk is a nonprofit organization that defines its mission as using new technologies to create a free, 3D online library of the world’s cultural heritage sites before they are lost to natural disasters, destroyed by human aggression or ravaged by the passage of time.

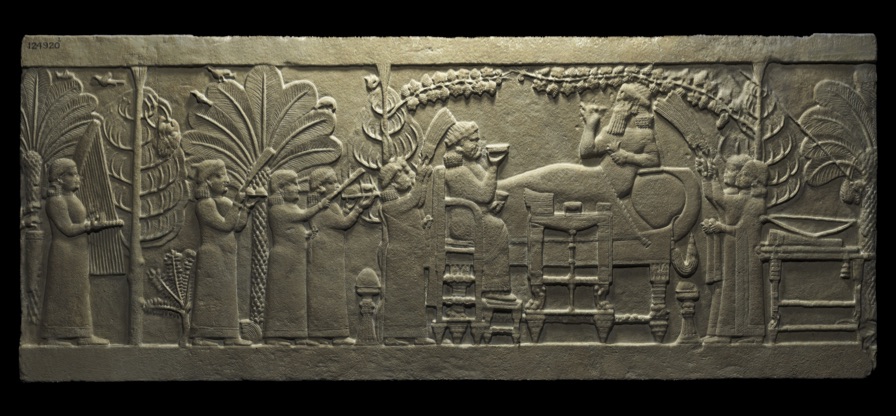

“The reliefs were originally commissioned by powerful Assyrian kings between the 9th and 7th centuries BC for their palaces, at a time when the small kingdom of Assyria, in what is now northern Iraq, expanded through conquest to dominate the Middle East, from the Persian Gulf to the Nile. The carved images range from symbolic scenes of royal achievements to scenes of conquest and hunting that all serve to glorify the Assyrian monarch,” says Matthew Cock, former Head of Web at the British Museum.

“The reliefs were acquired by the Museum in the late 1840s and 1850s as a result of the Treasury-sponsored archaeological expeditions of Sir Austen Henry Layard, who began his excavations at the North-West Palace of Ashurnasirpal at Nimrud in 1845. The first reliefs arrived in London in June 1847, followed soon by the monumental human-headed winged bulls. To accommodate them, the Assyrian galleries were created – between the Egyptian sculpture and Greek sculpture galleries – where they remain today.”

The images on the panels show an unfolding narrative, the story is revealed gradually as the viewer moves from one end of a panel to the other.

Over the past 160 years that the Assyrian reliefs and sculptures have been housed at the British Museum, its staff have continuously attempted to document them with the latest imaging technologies available, in order to facilitate the work of researchers studying the carvings. However, images, and even videos of the reliefs, can’t do justice to the scale of the narrative, so the museum’s staff decided to have CyArk 3D scan the reliefs.

Structured-light 3D scanning using the Artec Eva was one of the techniques used by CyArk. The team made 3D digital copies of the panels and artifacts in the Assyrian Galleries as well as artifacts in storage and those undergoing conservation. In just over two days they captured a total area of 205 square meters and collected 113 GB of raw data of geometry and texture.

From the scan data, CyArk attempted to create a new type of interpretive media – a video animation of the galleries. The appearance of a torch-lit ambience was added virtually to simulate that which might have been used at the Assyrian palace centuries ago.

The video below shows an early trial developed by CyArk using scans of the Siege of Lachish reliefs in Room 10b. Once finalized, the video should promote interest in Assyrian heritage and the Museum’s collection, helping researchers and the general public to develop a deeper understanding of this ancient culture and its art works.

To achieve this effect, raw data scans were processed then merged into 3D models via the Fast Fusion algorithm with the resolution of 0.5 to 0.9 mm (depending on the size of datasets). The Auto Alignment algorithm proved to be exceptionally useful (95% of the time this algorithm alone was sufficient), speeding up Global Registration, which took less than one hour to complete.

Processing the huge datasets turned out to be a real challenge for the team. To enable and accelerate the process of texturizing, they optimized the panels (typically decimated from ~20m faces) to ~4m faces, and employed a high-end Intel i7 machine. Nevertheless, the generation of texture maps took the longest time, about 6 hours, as the data would be left to process overnight.

The initial processing and texturizing was carried out in Artec Studio, the Eva’s “native” software. Normal maps were generated from diffuse textures in Adobe Photoshop (NVIDIA Normal Map filter) and supplemented with enhanced texture details rendering reflections of torch light. The 3D model of the Siege of Lachish from Room 10b was re-combined, lit, animated and rendered in Autodesk 3ds Max.

The scanning of the Assyrian Collection is part of CyArk’s initiative to archive cultural artifacts and promote the use of 3D technologies to the benefit of international museums.

The British Museum believes that 3D technologies may well become the primary method of recording collections in museums of the future and continues to digitize its collections and use the data to re-conceptualize current and future exhibitions, whilst giving open access to the 3D material produced.

Artec Eva Helps Bring Artwork to Life in 3D for Google Art Project

Summary: Google Art Project boasts tens of thousands of digitized pieces of artwork from across the world.

The Goal: To digitally capture in full-color, high-resolution 3D a whole range of art pieces, then turn them into 3D models for museums around the globe.

Tool Used: Artec Eva

Google’s online collection of museum exhibits expands with 3D models of artifacts scanned with Artec Eva.

A visual feast for art connoisseurs, Google’s online gallery includes over 90,000 digitized pieces of artwork from 500+ museums worldwide, and some of the items can be viewed in 3D thanks to Artec Eva. The scanner was integrated into a custom-made setup to create textured 3D models of artifacts, such as vessels, statuettes and pottery, in high resolution.

Courtesy of SlashGear.

Oddities and rare pieces of artwork can now be turned around and inspected from all angles.

“These objects are available – to the public – to be rotated and zoomed in on, allowing users to get up close and personal with them in ways never before possible, online or off,” says an article on slashgear.com. “Oddities and rare pieces of artwork can now be turned around and inspected from all angles, all thanks to 3D scanning technology Google is now making available to museums around the world for free.” SlashGear have also made a great video showing Eva at work during a 3D scanning session at Museo d’Arte Orientale in Turin, Italy.

3D Scanning and Printing a Bainbridge Water Fountain

Europac 3D was recently tasked with assisting a restoration specialist, Lost Art, to replicate a famous water fountain in Teesdale, Cumbria for a client who wanted to reproduce the piece in its full glory.

The scan needed to be carried out carefully to avoid any further damage to the fountain. This is where Europac 3D came into action with a unique combination of using Artec Eva and Artec Spider 3d scanners to capture the unique shape and dimensions of the water fountain.

The pair of scanners were particularly adept at scanning the fountain, being able to scan outside on a sunny day without any loss of accuracy or capture quality. They were used with a battery pack, which allowed for easy set up next to the fountain and freedom of movement, allowing for the operator to walk freely around the fountain with either of the handheld scanners.

The Artec Eva with its larger field of view was used to capture the larger smoother surfaces of the fountain sculpture, while the Spider was used to capture the detailed intricate parts. Both scans were captured in Artec Studio 12 software and the two sets of data were ‘married’ together to produce a watertight triangulated surface mesh. A unique feature of the Artec Studio 12 software allows for scans from different devices to be combined into one common point cloud and then merged to create a 3D model exactly as the client requested.

The 3D model was then printed in full-size in a ceramic plastic material using a Uniontech Pro Series 3d printer. The restoration artist was then able to add additional details and features such as intricate leaf details that had worn away from the original fountain

The final product was then cast in bronze using the 3d print as a mold template – Creating a new-meets-old final product of the famous Bainbridge water fountain for the client’s personal collection.