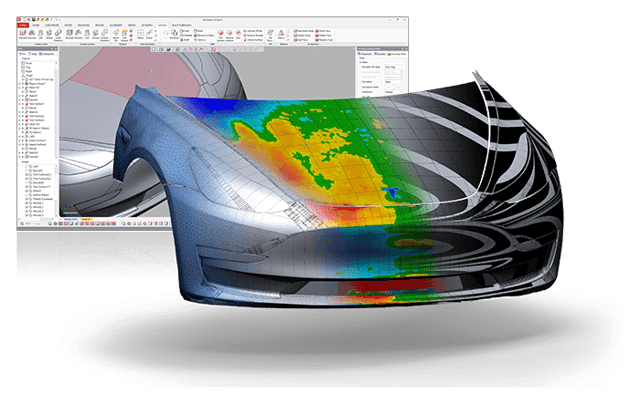

Reverse Engineering

Reverse engineering is a process where a physical part is deconstructed and measured in order to understand its design, how it works, and how it was made. This could be anything from a massive aircraft carrier or architectural structure, all the way down to a Swiss watch’s tiny set of interlocking gears.

Reverse engineering is used to scan a physical environment when no drawings or CAD data exist, or when as built drawings are outdated. Scanning allows our engineers to have confidence in the as built environment allowing us to compress our timelines on projects.

As opposed to a conventional design workflow, where you’re “starting from nothing” and creating a product from the ground up, in reverse engineering you start with an existing machine or component and work backwards, disassembling it either physically or digitally, part by part, or layer by layer, one step at a time.

The goal of reverse engineering is typically to create a useable 3D CAD model, and when done right, reverse engineering gives you the power to take this design information and achieve a number of objectives:

- Recreate legacy devices and parts, including via additive manufacturing technologies

- Conduct failure analyses on parts and machines, redesign as needed

- Deeply analyze the positives and negatives of a competitor’s product

- Easily replicate parts that are out-of-stock, extremely expensive, or have long wait times

- Improve the performance of any existing parts and systems

- Use the design information as a basis for creating an entirely new product

- And much more

Whether the objective is to capture the original design intent, new product development, product visualization, or part replication, 3Dimensional’s reverse engineering services are dependable, repeatable and cost effective.

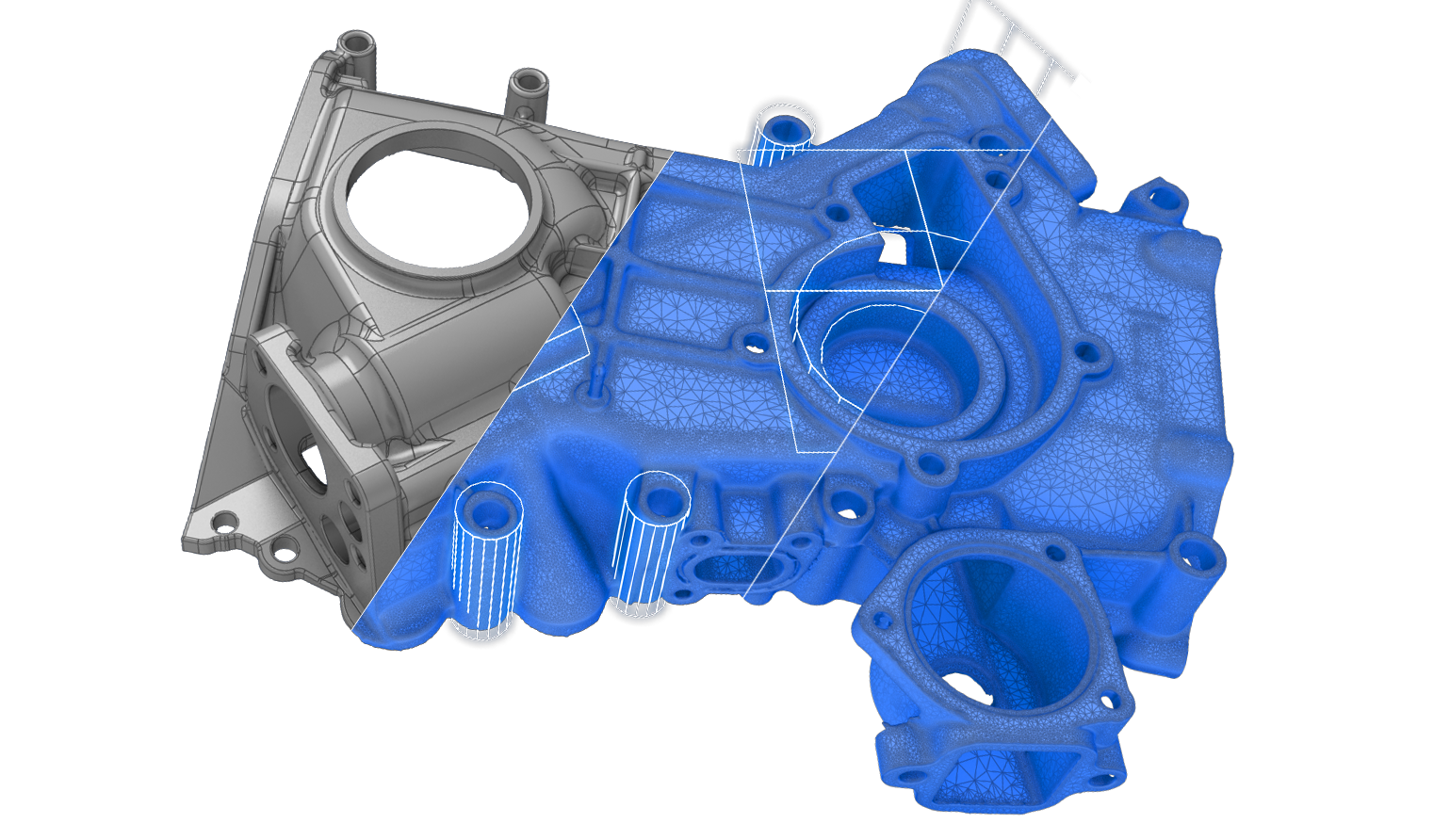

The process of reverse engineering using traditional methods such as calipers can be a long, tedious process and often uses a lot of guess work. The uses of 3D scan data avoids these methods and has the ability to capture 100% of the parts design. 3Dimensional utilizes its range of 3D scanning hardware to offer a reverse engineering service for virtually any component whether it be big, small, detailed or highly accurate.

Reverse engineering doesn’t finish after 3D scanning a part, often parts are imperfect and have manufacturing defects. We don’t want these imperfections in the end 3D model or drawings. 3Dimensional utilizes its portfolio of modelling software to offer a ‘full’ reverse engineering service whereby design intent can be analyzed and adjusted to create a perfect parametric solid model as if designed from scratch.