Quality Assurance

A robust inspection process to improve quality control is critical in today’s world of manufacturing. High quality inspection must begin with the highest quality ‘aerospace grade’ metrology equipment.

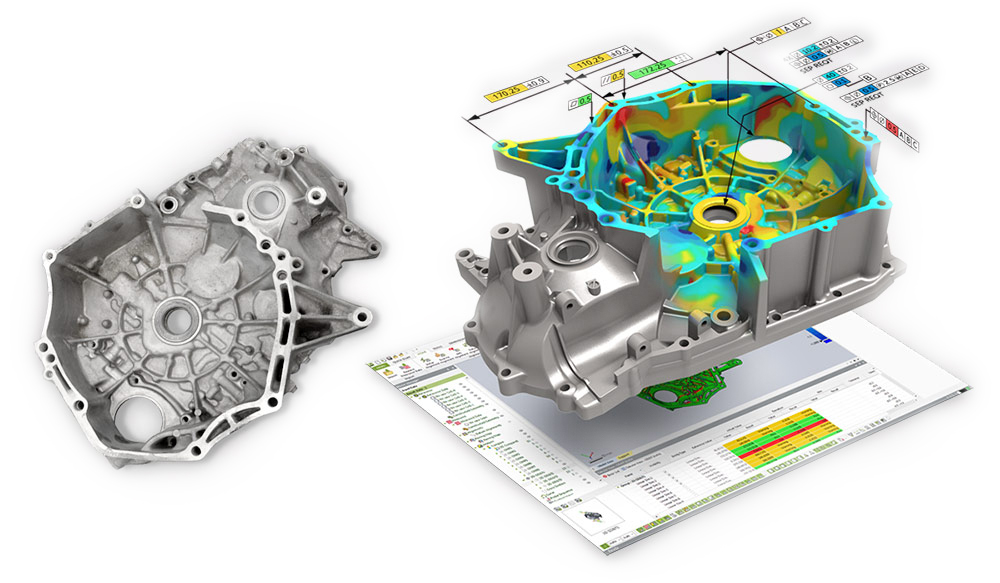

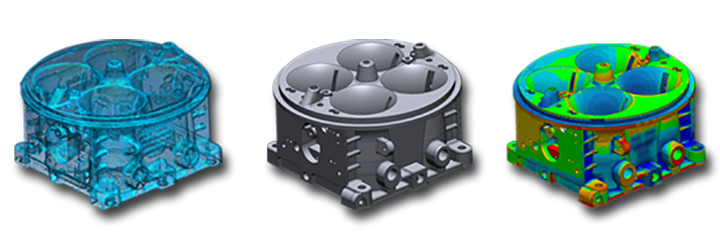

Once a physical part is scanned, its 3D data can be compared directly back to a CAD model to verify that the finished part or tooling conforms to the original design intent. Alternatively, two sets of 3D scan data can be compared with one another to assure that all parts are true to specifications. 3Dimensional typically produces color-coded inspection reports that represents our findings in a clear and readily understandable format.

Using 3D scanning for inspection allows the user to understand the shape and form of an object much better than traditional probing methods and therefore is especially useful for the inspection and verification of more organic freeform shapes. Full colour map inspection reports show exactly where surfaces are deforming, have excess material or are dimensionally incorrect.

The use of 3D scanning can verify the accuracy of the finished product. It can be analyzed in several ways to speed up current inspection workflow but also allows more complex analysis to be done.

The 3D measurement data from our scanners offers a comprehensive definition of a physical object that is used for measurement, inspection, comparison and reporting. When a part is defined by millions of points, you can see subtle deviations, slight variations and fine details, which gives you the confidence that a part (or mold) meets your specifications. To deliver the best of both worlds, we use 3D scanning tools to deliver precise dimensions on geometric shapes.