Automotive

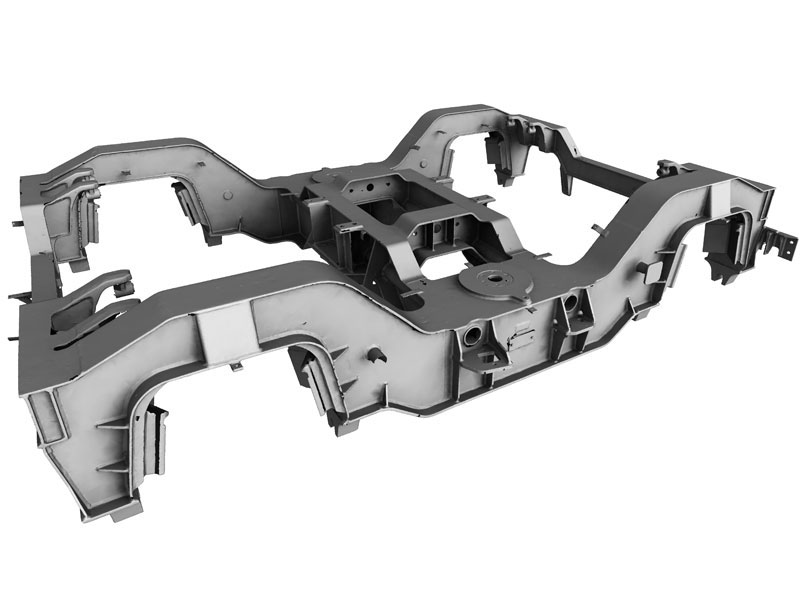

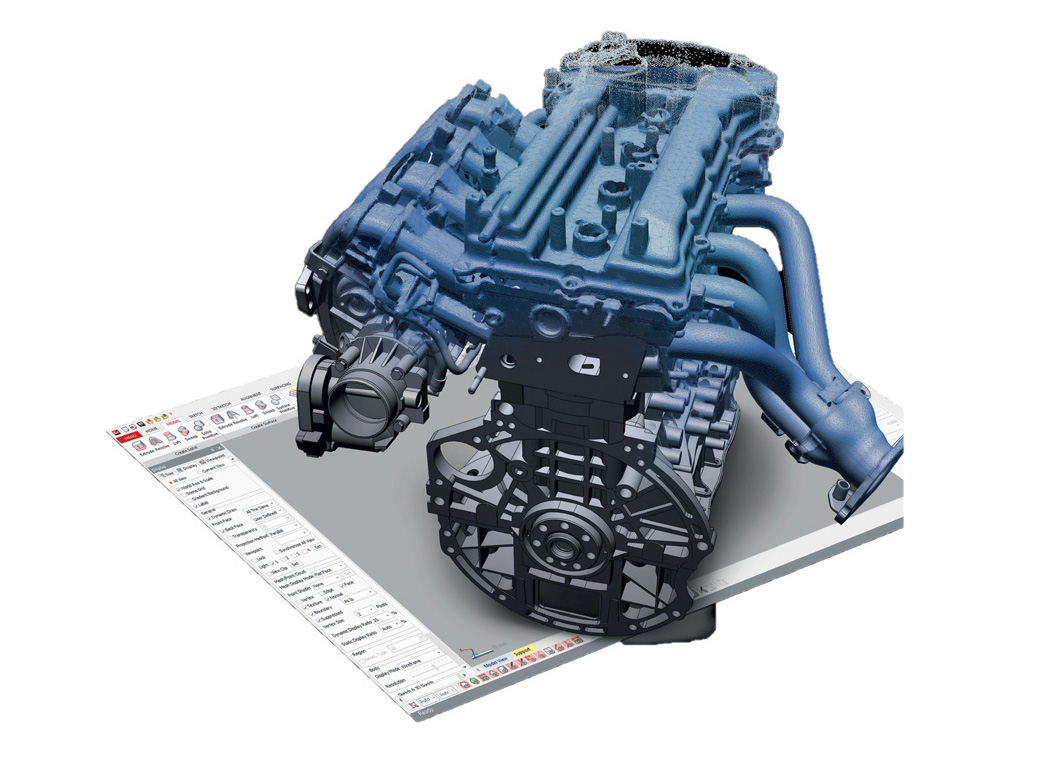

The aftermarket automotive parts industry has one of the most robust applications for 3D scanning today. When CAD is not readily available for safety, performance, or cosmetic car parts, 3Dimensional’s reverse engineering services can provide highly-accurate CAD models from existing automotive parts. CAD can be delivered in any desired format.

3D digitizing and metrology solutions can help engineers to perform reverse engineering and inspection of vehicles and parts, improving efficiency of product development and quality control.

With the rapid development of the automobile industry, various brand manufacturers are competing for excellence. In order to enhance the competitiveness of their products, automobile companies are carefully developing and designing more avant-garde, more creative, more comfortable, and more convenient car models that can satisfy the majority of consumers. In recent years, 3D scanning technology has been applied in the automotive industry.

The design process for new or improved automotive parts and assemblies includes the important step of producing, examining, and testing a physical prototype to observe how the product performs and note where it can be improved. Automotive engineers have always used prototypes in their work for iterative testing, but with rapid prototyping, this process can be done faster, more efficiently, and at a lower cost. Engineers and designers can benefit from having an automotive prototype to sample sizing and test for form, fit, feel, and function.

Besides automotive prototyping, 3D printing and additive manufacturing technologies can be used for producing parts for many automotive applications. Additionally, prototyping and production for automotive applications is not limited to small parts; multiple components can be joined to create very large items.

Vintage car restoration has its own set of challenges. One of which is locating rare or obsolete parts. You may have classic car insurance, but that won’t help you locate a discontinued OEM replacement part. 3D printing is now providing auto collectors a way to create their own parts for their modified car. Even with the advent of internet marketplaces, some classic car parts can be incredibly difficult to track down. Even if you do succeed in finding the part, often it will be extremely old or used. 3D printing allows you to custom make a brand new part to your exact specifications.

Vintage car restoration has its own set of challenges. One of which is locating rare or obsolete parts. You may have classic car insurance, but that won’t help you locate a discontinued OEM replacement part. 3D printing is now providing auto collectors a way to create their own parts for their modified car. Even with the advent of internet marketplaces, some classic car parts can be incredibly difficult to track down. Even if you do succeed in finding the part, often it will be extremely old or used. 3D printing allows you to custom make a brand new part to your exact specifications.

The process of 3D printing starts by scanning the desired part/s of the antique car. This detailed scan creates records of every curve and line of the vehicle. This scan is then fed into a computer and turned into a series of CAD drawings. A 3D printer can use these drawings to create the modified car part. The laser inside the printer then fuses together multiple layers of plastic, metal or carbon fiber to create an identical copy of the antique car part, accurate to the exact specification.